Preserves of whole tomatoes and tomato juice: those are the only ingredients needed to get the quality of Ciao products, other than a rigorous method to assure that everything is done to perfection. Let’s find out together from where the certainty of bringing the Neapolitan summer to the table comes from!

Carefulness, checks and method – these are the 3 keywords of the production of Ciao.

Our tomatoes arrive in your kitchen whole, perfect, fleshy, shiny and firm, because they are canned just a few hours from the harvest, but also because they are accurately checked throughout the production process.

Let’s see together how much care Ciao takes to keep the promise of always bringing the Neapolitan summer to the table.

The first production chain check is obviously that which takes place in the fields,

through agreements with farming cooperatives and the constant monitoring of crops and quantities planted per hectare. Thanks to precise agreements, vegetables not complying with the standards are rejected.

Then there are factory controls throughout the entire production process.

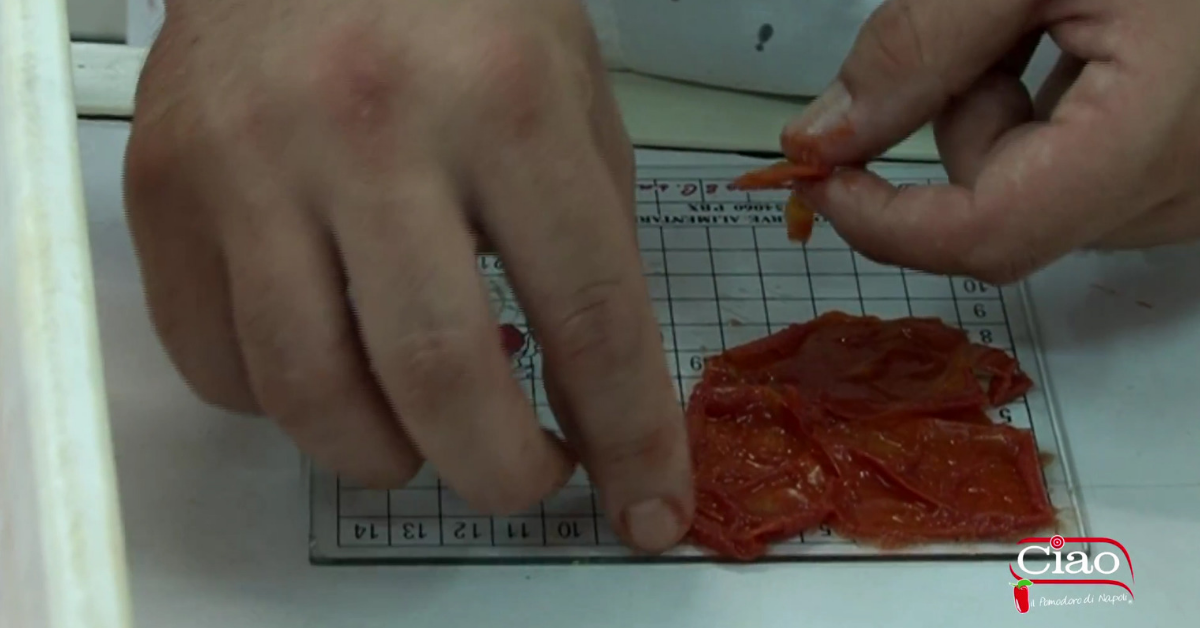

Checks of the tomato color that has to be perfect, sorting the greener and yellow tomatoes to keep only the red tomatoes.

Checks of the measure, to assure size homogeneity.

Checks of the tomato integrity after peeling them.

The last check before canning is the handmade inspection entrusted to the farm experience of our ladies of Vesuvius,

who with their eyes and hands complete the work of the machines.

This last step shows how for an historic brand like Ciao – Il Pomodoro di Napoli nothing can replace the human skills.

Ciao philosophy is a mix of hands and technology that uses innovation only as a means to make tradition safer.